Dobbie operates a modern innovative foundry and metals engineering complex, located in Perth, Western Australia. Established in 1940 but tracing its heritage in the Australia Foundry Industry all the way back to 1862, Dobbie is wholly Australian owned and has been manufacturing industrial products in both ferrous and non-ferrous materials for over 80 years.

Our traditional range of products includes waterworks valves, fire equipment, pump componentry, rail parts and bespoke cast components for the Defence, Heavy Industry and Resource sectors.

All our Australian manufactured products provide outstanding design quality, superior production oversight and excellent value for money.

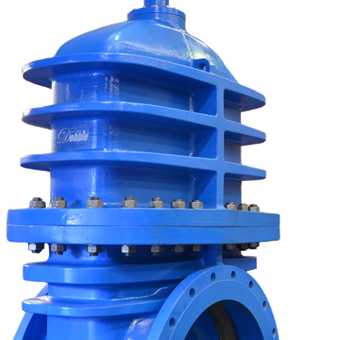

Dobbie Metal Seated Gate Valves have been designed and manufactured right here in Australia to suit the tough Australian conditions. Their heavy-duty construction features high abrasion resilience, robust impact resistance, prolonged exposure durability, extended service life and easy maintenance. They are suitable for a wide range of duties including:

• Mains Water Lines Trunk/Ring Mains

• Storm Water Sewer Lines

• Below Ground Fire Services Recycled Water

• Waste-Water Plants Static Water Stations

• Desalinisation Plants Pump Stations

Dobbie Metal Seated Gate Valves come in a range of configurations:

• Size range: DN80 - DN1800

• Pressure Rating: PN16 - PN35

• Non-Rising Stem

• Closure: ACC - CC

• Flange Connections: Table D / E or as per client specification (ANSI/ASME etc.)

• Actuation: Standard Stem Cap / Hand-wheel

• Actuation Options: Gearbox (Single/Dual Input)/Electric Actuator

Dobbie Metal Seated Gate Valves provide many benefits:

• AS/NZS 4020 approval making them well suited to applications involving the transfer and control of potable (drinking) water.

• Strong chemical compatibility, with highly abrasion resistant gates, are well suited to applications involving media contaminated with suspended particulates.

• As per AS/NZS 2638.1, valves are thoroughly tested to a minimum 1.5 times their rated operational pressure.

• Dobbie Metal Seated Gate Valves are additionally routinely tested to 5400Kpa thus making them especially suited to applications requiring high pressure and/or high temperature tolerance.

• Metal Seated Gate Valves present a clear, full bore waterway that will not inhibit flow.

• Suitable for above or below ground applications.

• Low torque values mean easy operation and extended service life.

• Minimal maintenance obligations.

• Scope:

• Size range: 80mm – 1000mm

• Style: Non-rising Stem (NRS)

• Closure: Anti Clockwise (ACC) or Clockwise (CC)

• Pressure Rating: PN16 or PN35

• Control: Handwheel or Stem Cap

• Actuation: Manual or Gearbox

• Connection: Flange AS 4087 or to client specification

• AS/NZS 4020 approved (suitable for use with potable water)

• AS/NZS 2638.1 Gate valves for waterworks purposes - Metal seated

• Application: Horizontal or Vertical

• Installation: Above Ground or Below Ground

• Materials:

? Body/Bonnet: Ductile Iron 400/12 (AS1831)

? Wedge:

? 80mm – 250mm – Gunmetal

? 300mm – 1000mm Ductile Iron 400/12 (AS1831)

? Spindle: #413 Stainless Steel

? Seats: Gunmetal

• Engineered and manufactured in Australia

• High abrasion resilience

• Robust impact resistance

• Extended Life Cycle – Durable, increased longevity.

Our traditional range of products includes waterworks valves, fire equipment, pump componentry, rail parts and bespoke cast components for the Defence, Heavy Industry and Resource sectors.

All our Australian manufactured products provide outstanding design quality, superior production oversight and excellent value for money.

Dobbie Metal Seated Gate Valves have been designed and manufactured right here in Australia to suit the tough Australian conditions. Their heavy-duty construction features high abrasion resilience, robust impact resistance, prolonged exposure durability, extended service life and easy maintenance. They are suitable for a wide range of duties including:

• Mains Water Lines Trunk/Ring Mains

• Storm Water Sewer Lines

• Below Ground Fire Services Recycled Water

• Waste-Water Plants Static Water Stations

• Desalinisation Plants Pump Stations

Dobbie Metal Seated Gate Valves come in a range of configurations:

• Size range: DN80 - DN1800

• Pressure Rating: PN16 - PN35

• Non-Rising Stem

• Closure: ACC - CC

• Flange Connections: Table D / E or as per client specification (ANSI/ASME etc.)

• Actuation: Standard Stem Cap / Hand-wheel

• Actuation Options: Gearbox (Single/Dual Input)/Electric Actuator

Dobbie Metal Seated Gate Valves provide many benefits:

• AS/NZS 4020 approval making them well suited to applications involving the transfer and control of potable (drinking) water.

• Strong chemical compatibility, with highly abrasion resistant gates, are well suited to applications involving media contaminated with suspended particulates.

• As per AS/NZS 2638.1, valves are thoroughly tested to a minimum 1.5 times their rated operational pressure.

• Dobbie Metal Seated Gate Valves are additionally routinely tested to 5400Kpa thus making them especially suited to applications requiring high pressure and/or high temperature tolerance.

• Metal Seated Gate Valves present a clear, full bore waterway that will not inhibit flow.

• Suitable for above or below ground applications.

• Low torque values mean easy operation and extended service life.

• Minimal maintenance obligations.

• Scope:

• Size range: 80mm – 1000mm

• Style: Non-rising Stem (NRS)

• Closure: Anti Clockwise (ACC) or Clockwise (CC)

• Pressure Rating: PN16 or PN35

• Control: Handwheel or Stem Cap

• Actuation: Manual or Gearbox

• Connection: Flange AS 4087 or to client specification

• AS/NZS 4020 approved (suitable for use with potable water)

• AS/NZS 2638.1 Gate valves for waterworks purposes - Metal seated

• Application: Horizontal or Vertical

• Installation: Above Ground or Below Ground

• Materials:

? Body/Bonnet: Ductile Iron 400/12 (AS1831)

? Wedge:

? 80mm – 250mm – Gunmetal

? 300mm – 1000mm Ductile Iron 400/12 (AS1831)

? Spindle: #413 Stainless Steel

? Seats: Gunmetal

• Engineered and manufactured in Australia

• High abrasion resilience

• Robust impact resistance

• Extended Life Cycle – Durable, increased longevity.

* All products may not be available at all stores, countries and regions.

Our partners

Proudly supporting Australian Made Campaign and the strength of the logo

Share