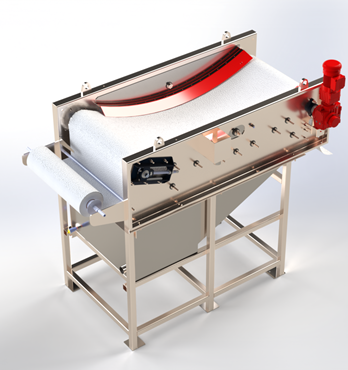

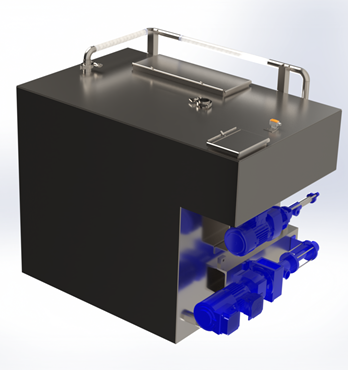

Dissolved Air Flotation (DAF) Systems

At Qtech Australia, we deliver precision-engineered solid-liquid separation systems that form the backbone of effective water and wastewater treatment.

Our Dissolved Air Flotation (DAF) units are designed to remove suspended solids, fats, oils, grease (FOG), and other contaminants—ensuring your system stays compliant, reliable, and efficient.

High-Efficiency Surface Clarification

Our DAF systems are built to achieve rapid and reliable clarification, removing low-density particles that conventional sedimentation systems can’t handle. Using fine microbubbles, contaminants are floated to the surface and skimmed away, leaving behind clean, clarified water.

Key Features:

• Automated Control – Integrated with SCADA/PLC for real-time adjustment, flow tracking, and load balancing

• High Removal Rates – Up to 95% removal of suspended solids, FOG, and BOD/COD

• Corrosion-Resistant Construction – Designed for long life in harsh environments

• Compact Footprint – Ideal for retrofits or space-constrained sites

• Custom Flow Capacities – From 10m3 per hour to 40m3 per hour

Applications Include:

• Industrial Wastewater

• Food & Beverage Trade Waste

• Slaughterhouse and Rendering Effluent

• Mining & Resource Processing

• Pre-treatment for Membrane Systems (RO/UF

At Qtech Australia, we deliver precision-engineered solid-liquid separation systems that form the backbone of effective water and wastewater treatment.

Our Dissolved Air Flotation (DAF) units are designed to remove suspended solids, fats, oils, grease (FOG), and other contaminants—ensuring your system stays compliant, reliable, and efficient.

High-Efficiency Surface Clarification

Our DAF systems are built to achieve rapid and reliable clarification, removing low-density particles that conventional sedimentation systems can’t handle. Using fine microbubbles, contaminants are floated to the surface and skimmed away, leaving behind clean, clarified water.

Key Features:

• Automated Control – Integrated with SCADA/PLC for real-time adjustment, flow tracking, and load balancing

• High Removal Rates – Up to 95% removal of suspended solids, FOG, and BOD/COD

• Corrosion-Resistant Construction – Designed for long life in harsh environments

• Compact Footprint – Ideal for retrofits or space-constrained sites

• Custom Flow Capacities – From 10m3 per hour to 40m3 per hour

Applications Include:

• Industrial Wastewater

• Food & Beverage Trade Waste

• Slaughterhouse and Rendering Effluent

• Mining & Resource Processing

• Pre-treatment for Membrane Systems (RO/UF

Where to buy

Where available

Country

Region

- Oceania/NZ

* All products may not be available at all stores, countries and regions.

Our partners

Proudly supporting Australian Made Campaign and the strength of the logo

Share